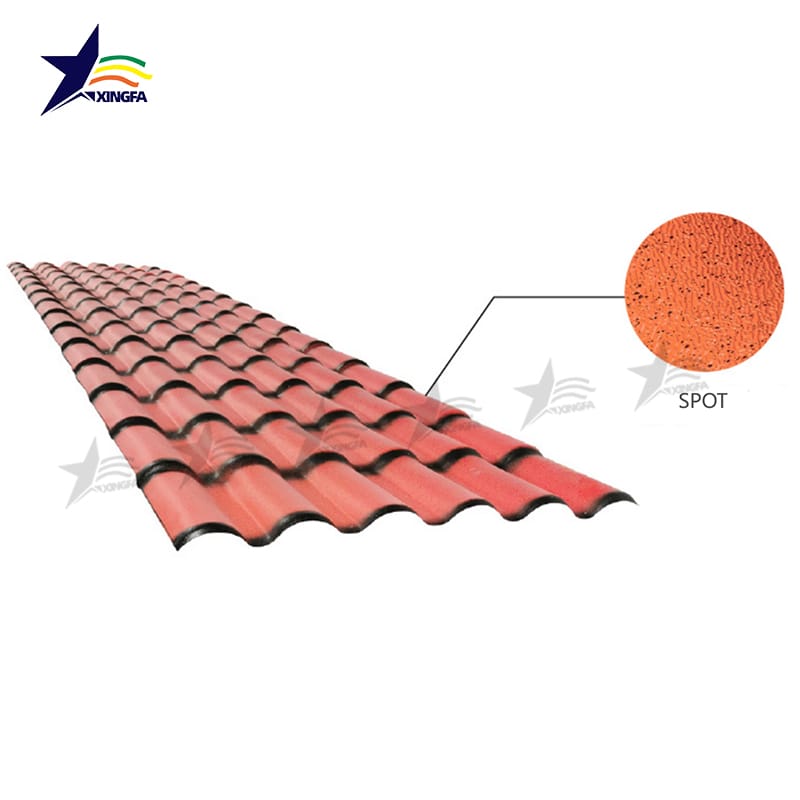

XINGFA Roma 1040 Roof Sheet With Spot

Width: 1040mm

Effecived Width: 940mm

Length: Customized

Thickness: 2.3mm, 2.5mm, 2.8mm,3.0mm

Application: Residential, Villas, Resorts, Hotels, Government Projects, ect.

Roma 1040 Roof Sheet With Spot

Roma 1040, using ultra-high weather-resistant and corrosion-resistant engineering resin ASA through advanced co-extrusion technology and a special molding process.

In some developed countries such as Europe and America, the use of synthetic resin roof tile has been used for several decades. So that it is applied to the roof of many buildings,

its more obvious advantage is that it has a gorgeous decorative effect and super waterproof performance, so that roof leakage and other phenomena no longer occur.

In addition, In low-temperature areas, even if the roof is perennial snow, the tile surface will not produce surface damage and fracture phenomenon.

Therefore, synthetic resin roof tiles are now widely used in many large, medium, and small projects, such as flat slopes, residential villas, awnings, farmers' markets, and other fields.

| Test Technical Data From SGS | ||||||||||||||||

| Item | Test Method | Test Condition | Result | |||||||||||||

| Thermal resistance | ASTMD3045-92(2010) | 150℃,30min | Visible deformation and colour fading, but no other visible change | |||||||||||||

| Vicat Softening temperature | ISO 306-2013 method B50 | Rate of temperature:50℃/h Load:50N | 77.3℃ | |||||||||||||

| Burning test | DIN 4102-1:1998-05 | Cotton indicator ignited by flaming particles or drops with V-2 | B2 | |||||||||||||

| Muriatic acid resistance | ISO 175-2010 | Immersion method Test time: 48h | 35%(m/m)HCL(AR) | No visial change | ||||||||||||

| Sulfuric acid resistance | ISO 175-2010 | Immersion method Test time: 48h | 30%(m/m)H2SO4(AR) | No visial change | ||||||||||||

| Alkali resistance | ISO 175-2010 | Immersion method Test time: 48h | 40%(m/m)NaOH(AR) | No visial change | ||||||||||||

| Xenon-arc Exposure | ISO4892-2:2013 ISO 105-A02:1993/Cor.2:2005 ASTM D2244-11 | Irradiance:(0.51±0.02)W/(m2·nm)@340nm 102 min light at (63±3)℃ BPT, (50±10)% RH 18 min light and water spray Filter: Boro/Boro Exposure Period: 500h | Grey Scale: 2-3 △Eab=3.5 | |||||||||||||

| Flexural strength | ISO 178:2010/Amd.1:2013 method A | Testing speed: 1mm/min span:50mm | 41.3Mpa | |||||||||||||

| Impact Resistance | GB/T 8814-2004 Section 5.7 Section 6.7 | Condition: -10℃ , 1h →Take out and do the test within 10s Geometry: H.25 Strik weight:1.0kg Span:200mm No. of specimen tested:10 | breakage:0 | |||||||||||||

| Thermal conductivity | ASTM C518-17 | Condition the test specimen at(23+2)°C and(50+5)% relative humidity to constant mass | 0.09(W/m·K) | |||||||||||||

| Thermal resistance | 0.03(m2·K)/W | |||||||||||||||

| Tensile Breaking strength | GB/T 1040.2-2006 | Span:115mm Specimen width: 25mm Power: 1050N | 21.53Mpa | |||||||||||||

| Tensile Strength | GB/T 1040.2-2006 | Span:115mm Specimen width: 25mm Power: 1050N | 22.56Mpa | |||||||||||||