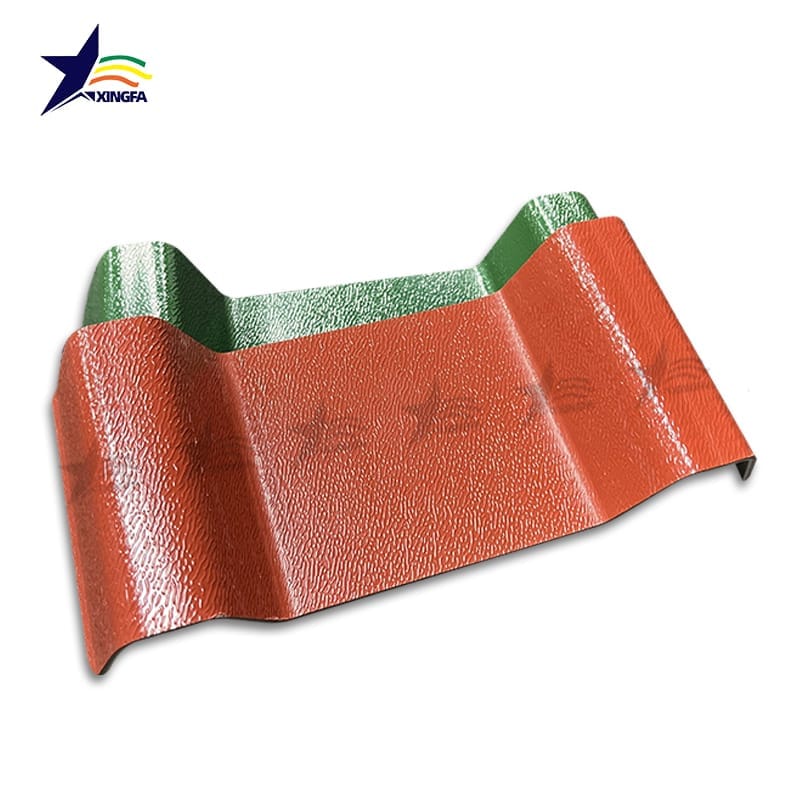

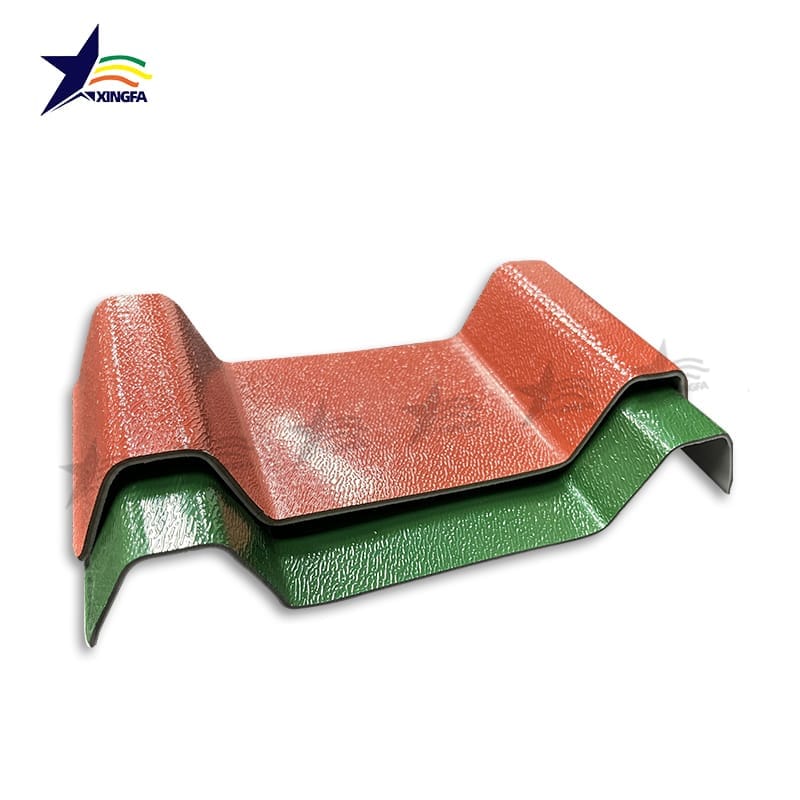

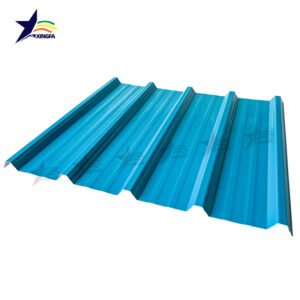

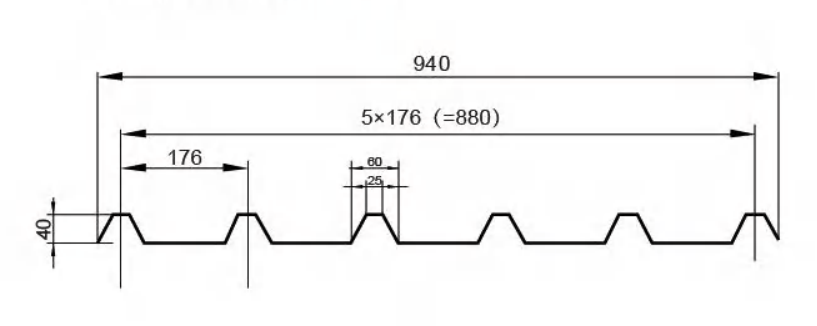

XINGFA ASAPVC Trapezoidal H940 Specification

Width: 940mm

Efficient Width: 880mm

Length: Customized

Thickness: 2.0mm,2.3mm,2.5m,2.8mm,3.0mm

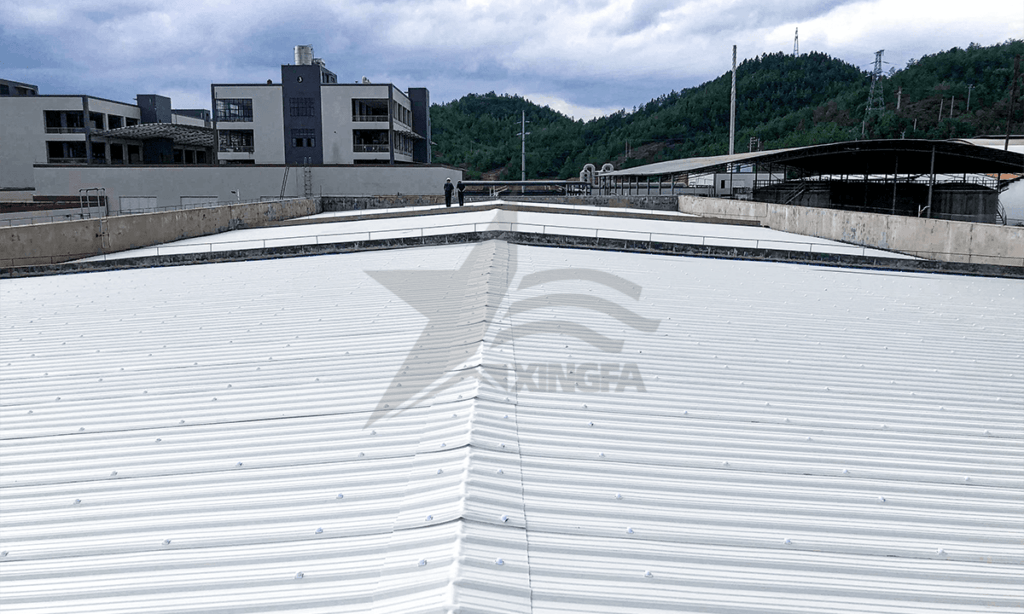

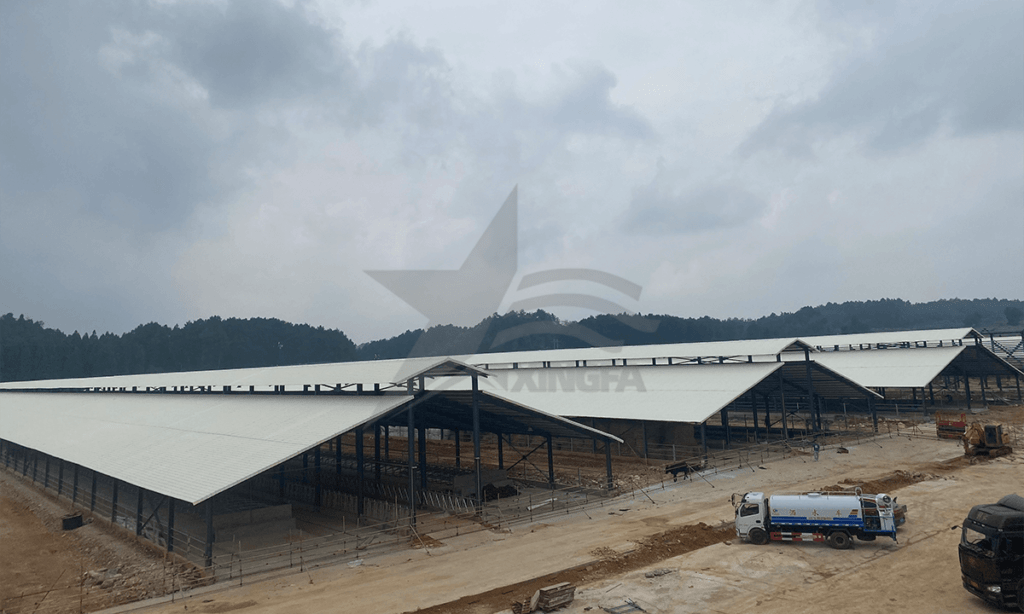

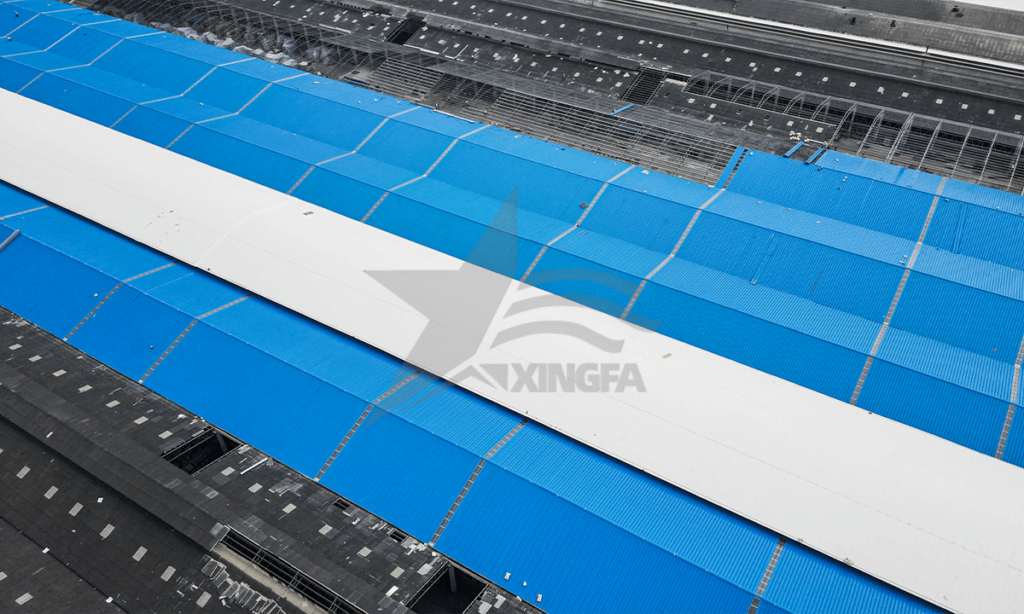

Application: Sheds, Workshops, Parking Lots, Production Workshops, Greenhouses, Farms, Chemical Plants, ect.

XINGFA ASAPVC Trapezoidal H940 Specification

Over the past two decades, PVC roof panels have already been utilized in various kinds of business and gardening components around the globe.

From hog barns to dairy food storage sheds or poultry properties, vehicle washes, substance-finalizing plants and flowers, or fertilizer-storing establishments.

Due to its strength and durability, PVC roof panels typically have a long service life. In addition, Corrugated plastic roofing sheets are easy to install using regular resources.

| Test Report | ||||||||||||||||

| Item | Test Method | Test Condition | Result | |||||||||||||

| Thermal resistance | ASTMD3045-92(2010) | 150℃,30min | Visible deformation and colour fading, but no other visible change | |||||||||||||

| Vicat Softening temperature | ISO 306-2013 method B50 | Rate of temperature:50℃/h Load:50N | 77.3℃ | |||||||||||||

| Burning test | DIN 4102-1:1998-05 | Cotton indicator ignited by flaming particles or drops with V-2 | B2 | |||||||||||||

| Muriatic acid resistance | ISO 175-2010 | Immersion method Test time: 48h | 35%(m/m)HCL(AR) | No visial change | ||||||||||||

| Sulfuric acid resistance | ISO 175-2010 | Immersion method Test time: 48h | 30%(m/m)H2SO4(AR) | No visial change | ||||||||||||

| Alkali resistance | ISO 175-2010 | Immersion method Test time: 48h | 40%(m/m)NaOH(AR) | No visial change | ||||||||||||

| Xenon-arc Exposure | ISO4892-2:2013 ISO 105-A02:1993/Cor.2:2005 ASTM D2244-11 | Irradiance:(0.51±0.02)W/(m2·nm)@340nm 102 min light at (63±3)℃ BPT, (50±10)% RH 18 min light and water spray Filter: Boro/Boro Exposure Period: 500h | Grey Scale: 2-3 △Eab=3.5 | |||||||||||||

| Flexural strength | ISO 178:2010/Amd.1:2013 method A | Testing speed: 1mm/min span:50mm | 41.3Mpa | |||||||||||||

| Impact Resistance | GB/T 8814-2004 Section 5.7 Section 6.7 | Condition: -10℃ , 1h →Take out and do the test within 10s Geometry: H.25 Strik weight:1.0kg Span:200mm No. of specimen tested:10 | breakage:0 | |||||||||||||

| Thermal conductivity | ASTM C518-17 | Condition the test specimen at(23+2)°C and(50+5)% relative humidity to constant mass | 0.09(W/m·K) | |||||||||||||

| Thermal resistance | 0.03(m2·K)/W | |||||||||||||||

| Tensile Breaking strength | GB/T 1040.2-2006 | Span:115mm Specimen width: 25mm Power: 1050N | 21.75Mpa | |||||||||||||

| Tensile Strength | GB/T 1040.2-2006 | Span:115mm Specimen width: 25mm Power: 1050N | 22.7Mpa | |||||||||||||