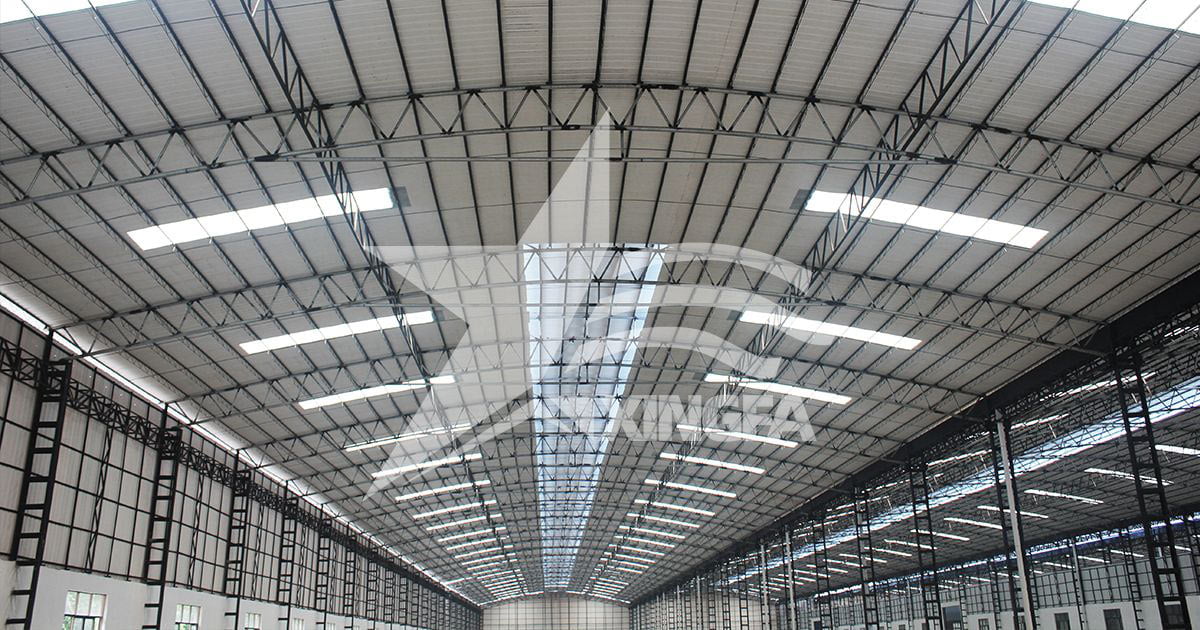

PVC Translucent Tiles, as a building material that can improve the lighting of buildings, have been deeply loved by the public and widely used in various fields. PVC Translucent Tiles are beautiful in shape, rich in color, energy-saving and environmentally friendly, and have good light transmittance. They are now widely used for lighting. The installation of PVC Translucent Tiles is not complicated, but some details should be paid attention to.

1. Before fixing the PVC Translucent Tiles, pre-drilling is required, and the hole diameter must be 50% larger than the diameter of the fixing screw to avoid thermal expansion and contraction causing internal stress cracking of the PVC Translucent Tiles.

2. PVC Translucent Tiles are fixed with aluminum profile fasteners, wave-shaped PVC Translucent Tiles are fixed with PVC Translucent Tiles brackets and self-tapping screws, and then sealed with glue. The position of the PVC Translucent Tiles is generally set in the middle of the span.

3. When the PVC Translucent Tiles are connected in the longitudinal direction with the steel plate, there must be a minimum overlap of 200mm, and two water stop belts must be pasted.

4. When the PVC Translucent Tiles are connected with self-tapping screws, a cover plate must be provided. The cold and hot deformation of the sun plate is large and easy to be cut off by self-tapping screws, so a large hole should be opened at the place where PVC Translucent Tile is punched. The expansibility of the sun plate should be considered when installing PVC Translucent Tiles.

5. When fixing PVC Translucent Tiles, a good waterproof gasket must be used to make it between the screw and the PVC Translucent Tiles to prevent water and dust. After the waterproof gasket is put into the screw, it is locked into the beam with an electric drill, which completes the fixing work of the PVC Translucent Tiles.

6. PVC Translucent Tiles do not need to be connected within 12m, and if they exceed 12m, they need to be connected. The connection length is 200-400mm, and two sealing glues are applied at the connection. No edge is required for the transverse connection, and the longitudinal color steel plate depends on the board type. Generally, no edge is considered for ordinary press-type steel plates, and it is directly fixed with self-tapping screws and sealed with sealing glue. The edge should be made for the bite plate.

7. When constructing PVC Translucent Tiles, it is strictly forbidden to step directly on the wave peak to avoid cracking of the PVC Translucent Tiles. A 1200mmx300mm (length x width) anti-skid thick wood board must be placed in the transverse position of the PVC Translucent Tiles, and the feet should be stepped on it for pre-drilling and fixing screws of the PVC Translucent Tiles.

These are the installation methods and precautions for PVC Translucent Tiles. Proper installation can ensure the quality of PVC Translucent Tiles. If you have any questions, please feel free to contact us, Foshan Xingfa Tile Industry, a new environmental roofing material manufacturer.