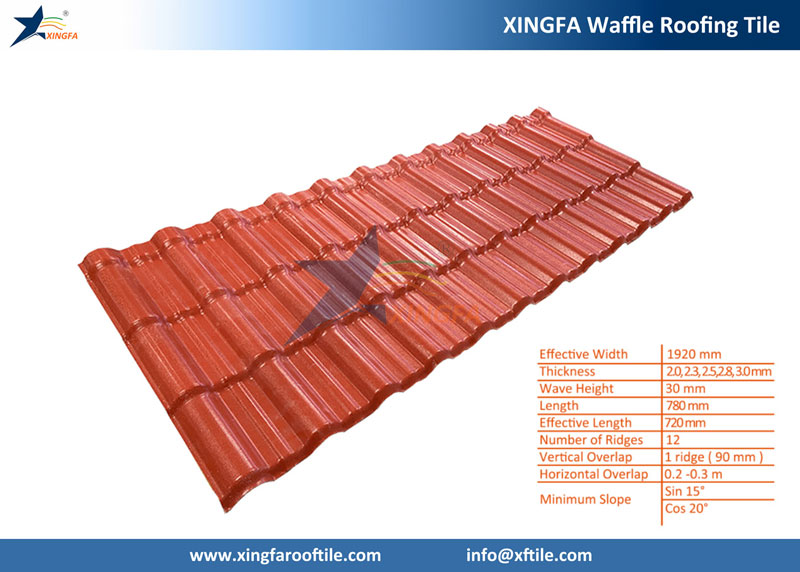

The national standard for synthetic resin tiles is generally 0.72M and 0.88M, with a thickness of 3MM and a weight of 6KG per square meter. Standard synthetic resin tiles will provide relevant inspection reports from the National Chemical Building Materials Testing Base when they are purchased (they are not allowed to be sold in the market without the inspection report from the National Chemical Building Materials Inspection Base):

- Artificial aging inspection report (artificial aging for 10,000 hours is equivalent to more than 20 years of actual use)

- Low-temperature drop hammer impact (0℃, 1h) inspection report (a one-kilogram steel ball falls freely on the tile surface from a height of 1 meter without cracking, and the product is not damaged after 10 freeze-thaw cycles. After 10 freeze-thaw cycles, the product has no hollowing, blistering, peeling, cracking and other phenomena.) Standard synthetic resin tiles have very good load-bearing performance. After inspection by the National Building Materials and Components Quality Supervision Station, there is no damage when the support distance is 750MM and the uniform load is 150KG. Inferior synthetic resin tiles will break when workers step on them during construction.

- Fireproof building materials inspection report (Building interior decoration design fire protection standard A2.6 plastic combustion performance determination B1 level or above)

- Standard synthetic resin tiles can resist corrosion by various chemical substances such as acid, alkali, salt, etc. for a long time. The test shows that there is no chemical reaction in salt, alkali and various acids below 60% for 24 hours. The pigment used in the surface layer of inferior synthetic tile roofing will react chemically and even fade.