Synthetic Resin tiles, as an innovative building material, have their origins traced back to early 20th-century Germany. Through years of research and development, resin tiles have continuously improved their performance and manufacturing processes, becoming a favored roofing material.

At that time, a German chemist named Bakelite and his assistants embarked on research on synthetic resins. Their initial goal was to find a substitute for natural resin insulation varnish. After three years of hard work, they successfully produced a synthetic plastic material called phenolic resin (Bakelite), also known as “electric wood” or “synthetic wood.” The discovery of phenolic resin marked a significant breakthrough in synthetic resin materials. This new material, with its plasticity, chemical resistance, and heat resistance, made it widely used in construction and other fields.

Over time, research and development of resin tiles have made significant progress. In the early 21st century, a manufacturer in China drew inspiration from clay and glass tiles and achieved the mass production of resin tiles through co-extrusion technology. Initially using multi-layer co-extrusion technology, they later applied surface film (ASA film) technology, significantly enhancing the color richness and durability of resin tiles.

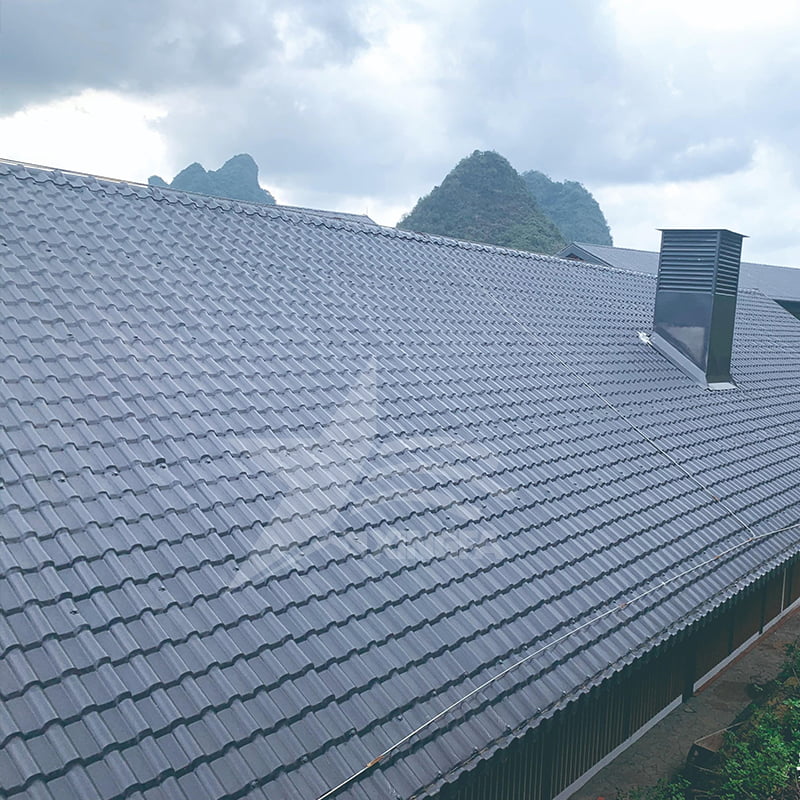

Today, resin tiles have become a common roofing material. Their lightweight, durability, longevity, and wide range of color choices have made them widely used in modern architecture. Whether in residential, commercial, or industrial buildings, resin tiles provide a reliable roofing solution.