PVC hollow tile is a new environmentally friendly material widely used in modern building roofing. Its main raw material is polyvinyl chloride (PVC). This kind of tile adopts a unique hollow multi-frame structure design with a hollow interior. It cleverly uses air as the insulation medium to effectively block the transfer of cold and heat, achieve excellent thermal insulation effect, and help save energy and reduce consumption.

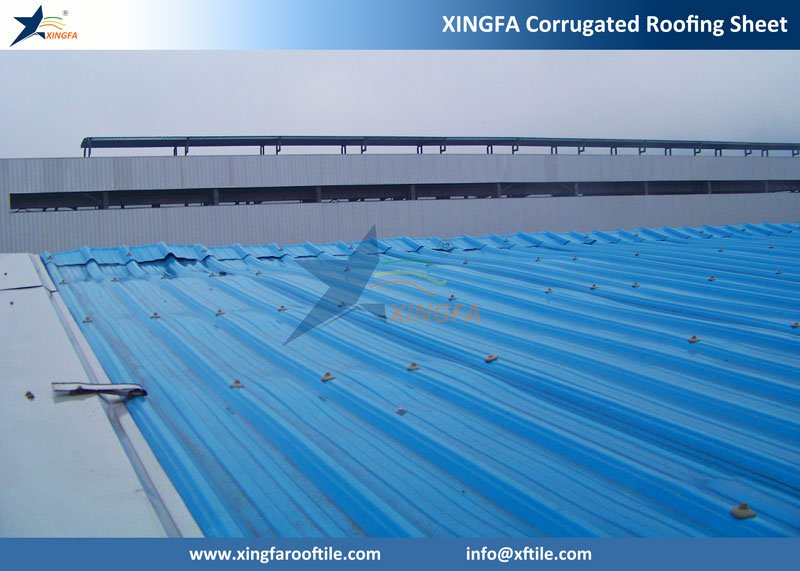

The dense reinforcing rib system inside the PVC hollow tiles not only ensures that the product has good rigidity and bending strength, allowing the tiles to withstand larger roof loads, but also reduces the requirements for the roof truss support structure. At the same time, its edges and seams adopt advanced waterproof groove or buckle designs to ensure excellent waterproof performance under various climate conditions and avoid the risk of rainwater leakage.

In addition, the PVC material itself has excellent weather resistance, anti-aging and certain flame retardant properties. Combined with surface treatment technologies such as ASA weather-resistant layer, PVC hollow tiles can maintain stable performance and color in long-term outdoor environments and extend their service life.

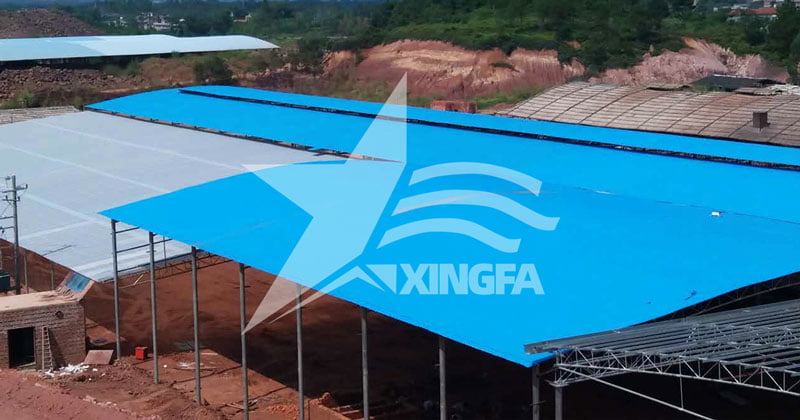

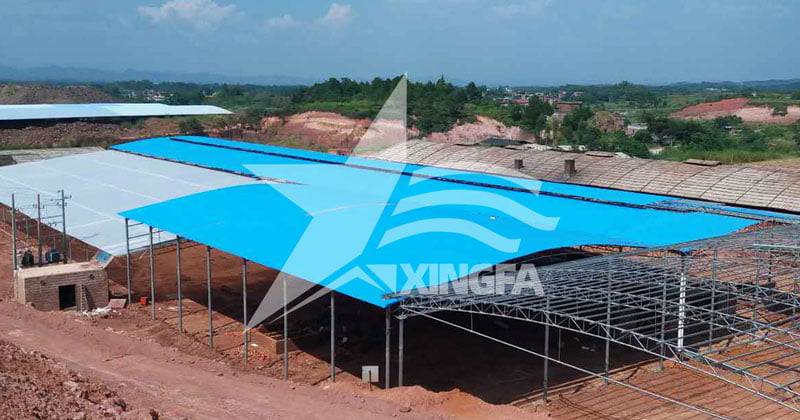

In summary, PVC hollow tiles have become an ideal roof covering material for various types of buildings such as industrial plants, warehouses, greenhouses, etc., due to their multiple advantages such as lightness and durability, thermal insulation, waterproof and seepage-proof, beautiful and environmentally friendly, and are well received by the market. favor.