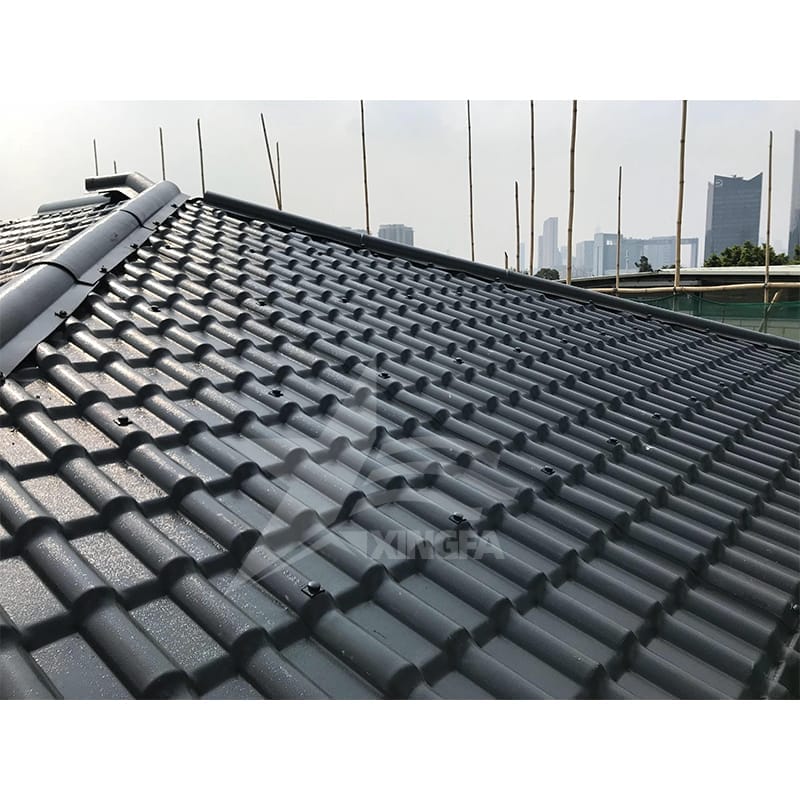

As a new type of roofing material, the synthetic resin tile has been widely used in the building industry. It has a variety of advantages, such as the color of long-lasting, light quality, self-waterproof, tough, heat insulation, sound insulation, corrosion resistance, wind and shock resistance, hail resistance, anti-pollution, green environmental protection, fire prevention, insulation and convenient installation. The following will introduce the production process of the synthetic resin tiles.

First, the first step in making synthetic resin tiles is raw material preparation. We need to prepare the resin, filler and reinforcing materials.

Next was the step of mixture preparation. Mix the glass fiber and the resin in proportion.

After completing the mixing, we entered the molding stage. The mixture was poured into a preprepared mold for molding. The design of the mold determines the shape and texture of the final resin tile. In the mold, the mixture solidifies gradually.

The formed resin tiles need to be cured to improve their strength and hardness. This can be accelerated by placement in a thermostatic chamber for thermal curing or by using a chemical curing agent. The time and conditions of curing will vary depending on the type of resin used and the manufacturer’s specification.

Once the resin tile is cured, we need to cut and trim it to meet the specific size and shape requirements. Through professional cutting tools and techniques, the resin tile can be accurately sized.

At this time, the resin tile has been made, but the quality inspection needs to be conducted before leaving the factory. Appearance inspection, dimension inspection and strength test are indispensable to ensure that the product meets the relevant standards and requirements.